Secomak Industrial HeatPack: Redefining Heat Processing with Precision, Portability and Efficiency

Secomak is proud to present the Industrial HeatPack for consideration in the PPMA Automate Awards for Innovative Processing System, a category that celebrates engineering excellence in enhancing productivity, improving safety, and driving cost savings.

With more than 95 years of expertise in blower and heater technology, we have brought together two of our core innovations into one intelligent solution. The Industrial HeatPack is a powerful and adaptable hot air system designed with both efficiency and ergonomics. Setting a new benchmark for performance across a wide range of industries, including pharmaceuticals, aerospace, food and beverage, manufacturing and defence.

Innovation Through Intelligent Integration

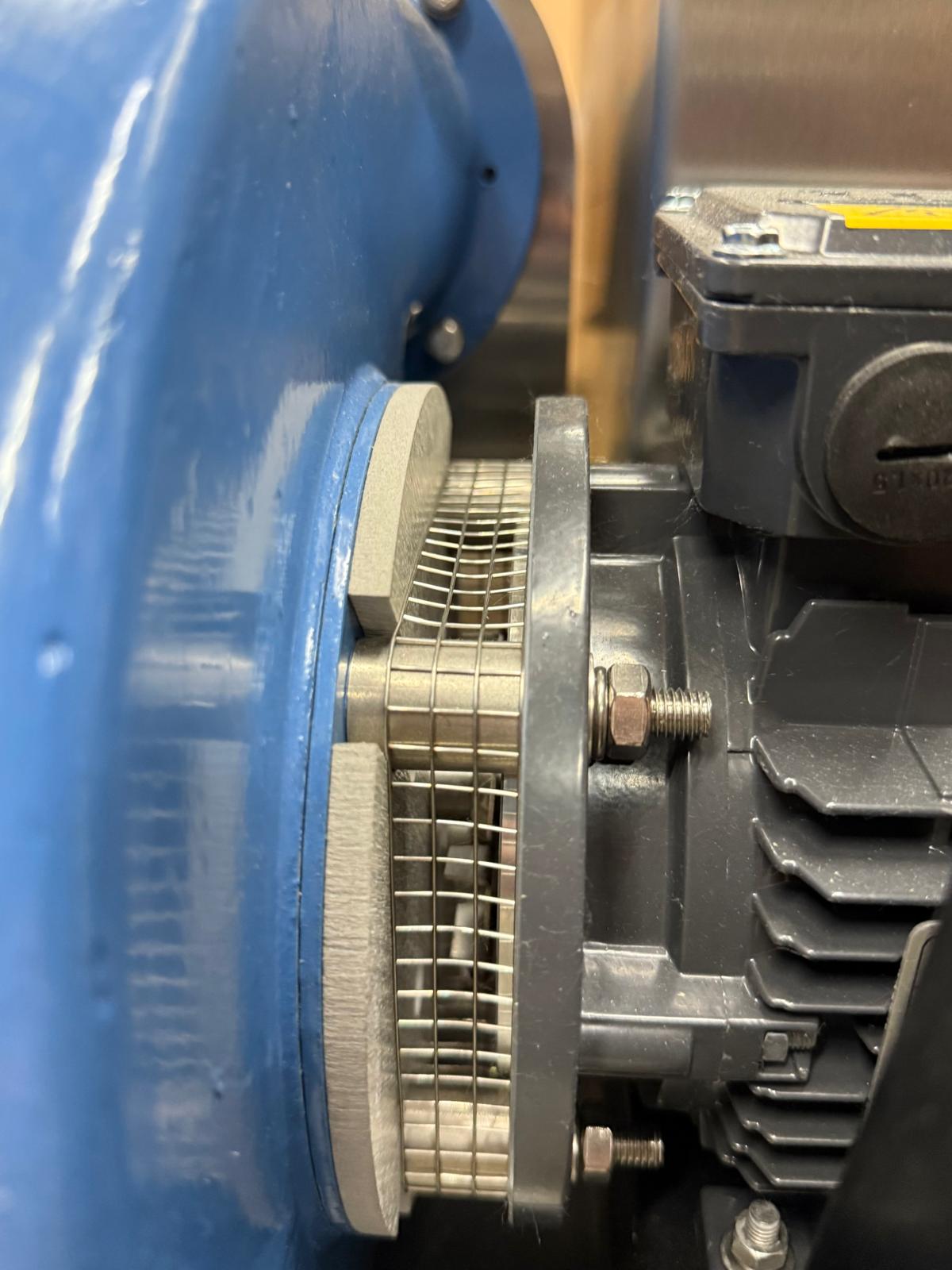

At its core, the HeatPack incorporates Secomak’s direct-drive centrifugal fan, developed specifically for hot air recirculation. This design enables the fan to withstand inlet temperatures exceeding 200°C while delivering consistent airflow and thermal performance. By recirculating hot air the system significantly reduces energy consumption, requiring less power to maintain high operating temperatures. This translates into significantly lower running costs without compromising throughput.

Our advanced heater design ensures rapid heat-up and precise thermal control, achieving outlet temperatures of up to 400°C. When paired with solid-state relay controls, the HeatPack delivers temperature accuracy within ±1%, guaranteeing product integrity and consistent processing even in the most demanding applications.

Demonstrating this innovation a bespoke HeatPack was designed for an aerospace customer in the United States specialising in rocket propulsion. Their challenge was to reduce thermal heat-up times for large copper components used in thrust chamber welding. The HeatPack was engineered to recirculate air at temperatures of up to 300°C while operating reliably without supervision.

To support their workflow, our controls engineer programmed the system for remote activation at 3am. By the time the shift began at 8am, the components were pre-heated and ready for immediate welding. The stand-off motor design ensured the fan, motor, and heater assembly could withstand the extreme recirculation temperatures without damage, delivering both reliability and performance in a highly critical environment.

Performance Made Portable

The HeatPack is designed to be production-ready from the moment it arrives. Its portable trolley system and quick-connect power supply make it simple to move across production lines, offering an ideal solution for sites that require heat processing in multiple locations.

With power ranges from 1kW to 36kW, every HeatPack can be tailored to specific customer requirements. Blower sizing and heater configuration are optimised to deliver the best performance for each unique application.

Case Study: GlaxoSmithKline

GlaxoSmithKline approached us with a clear objective: reduce operational overheads while increasing productivity. The solution came through two compact HeatPacks.

The application, while straightforward in appearance, required precision and expertise. During pill manufacturing, intermediate bulk containers (IBCs) are filled with raw powder and transferred to the mixing room. Once the powders are mixed and decanted, the IBCs must be thoroughly cleaned and dried before reuse.

Previously, this drying was done by hand, often limiting the team to just twelve IBCs in a single shift. With the introduction of the HeatPack, drying time was cut to only five minutes per container, boosting productivity by ten fold.

For a site the size of GSK, portability was also crucial. The HeatPacks we supplied were built on portable trolleys with lockable castor wheels, allowing effortless movement between factory sections without the need for lifting equipment. The result was a safe, mobile solution that combined ease of transport with reliable, stable operation.

Smart Control, Smarter Results

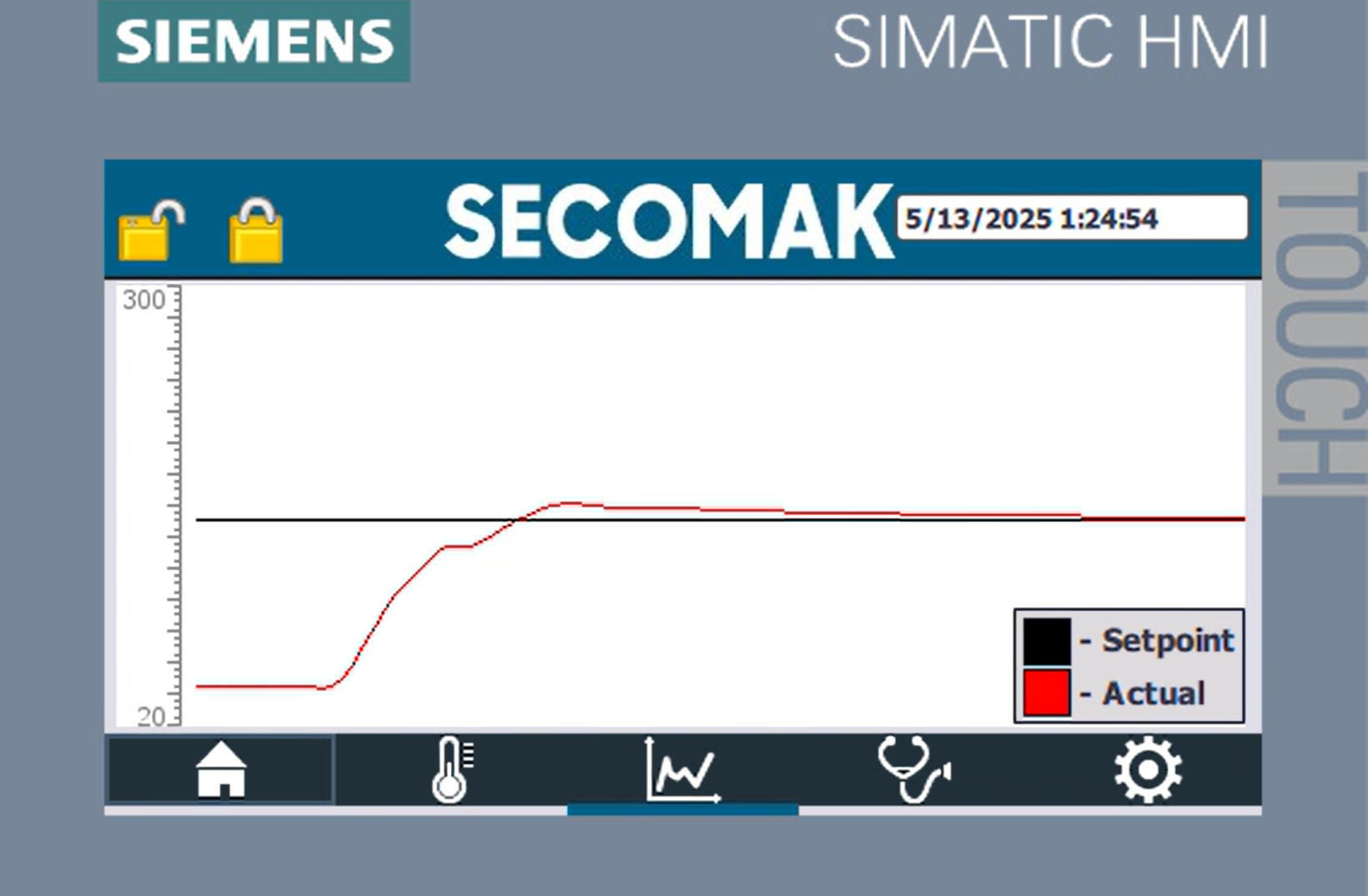

One of the most exciting recent innovations is the new HMI (Human Machine Interface) control panel, a fully integrated touch-screen system that puts the operator in complete control.

Key HMI features include:

- Simple temperature setpoint control

- Live trend lines of actual vs. target temperature

- Customisable high/low temperature alarms (local or remote via BMS)

- Blower speed control

- Real-time power consumption monitoring

- Energy savings metrics via recirculation feedback

This smart control system delivers an intuitive and intelligent user experience, promoting not only ease of use but better process decisions and reduced operator error.

Advanced Cryogenic Heatpacks for Extreme Conditions

This year we delivered two cryogenic Heatpacks to a military aerospace customer. These machines can switch seamlessly between hot air at 180 °C and freezing temperatures down to -60 °C using liquid nitrogen. This was a completely new challenge for Secomak and our team embraced it fully.

Our design engineers worked closely with material and component suppliers to make sure every part could handle these extreme temperatures. Once the mechanical design was finalised the focus shifted to controls. Safety and precision were of paramount importance. Real-time heat trend monitoring, emergency alarms and careful temperature regulation were all implemented to ensure reliable operation.

The HMI was designed to be clear and intuitive allowing operators to monitor processes in real time. Supporting this, twenty thermocouples continuously provide temperature feedback and each one can act as the master to maintain safety and control. The Heatpack demonstrates Secomak’s ability to deliver precise engineering, dependable controls, and full operational safety.

Proven Impact and Industry Validation

Customer feedback has been overwhelmingly positive, highlighting:

• Unmatched ease of use

• Reliable and consistent hot air delivery

• Immediate operability with minimal setup

In real-world applications, customers have reported faster heat-up times, more consistent processing, and improved energy efficiency. These benefits translate into measurable improvements in productivity and significant cost savings across a range of industries.

Real-World Validation

Proving the effectiveness of the HeatPack is often straightforward, as we have highlighted throughout this article. One compelling example comes from a wheat processing plant that has relied on a Secomak HeatPack for decades to dry their pipes and ducting following Clean-In-Place (CIP) procedures.

Downtime at this facility is a critical concern, with the drying process for ducting and pipes traditionally taking up to 13 hours. With production losses estimated at £500 per hour, the plant sought our help to accelerate this process.

During a trial period, the HeatPack reduced drying time to under one hour—a saving of up to 12 hours per cleaning cycle. Considering the plant sometimes performs CIP up to five times a week, the resulting cost savings and return on investment are substantial, demonstrating the tangible value our HeatPack.

Conclusion: A Step Change in Heat Processing

The Secomak Industrial HeatPack represents a genuine leap forward in thermal processing. By combining our long-standing expertise in airflow and heating technology with modern controls and innovative design, we have created a flexible, intelligent, and sustainable solution that meets the industry’s growing demand for precision, portability, and energy efficiency.

When you consider all the key features of the Secomak HeatPack range, it is clear why our customers rely on it so consistently. Across the industries we serve, end users trust the HeatPack to improve their processes and achieve better results every time.

Whether the goal is to improve output, reduce operational costs, or enhance system control, the HeatPack is already delivering measurable value across multiple industries. This makes it a strong contender for the PPMA Award for Innovative Processing System.